POLO lifting stations are practical and useful units for conveying contaminated liquids with a high chip content from a filter system. Small space required are their features.

Lifting stations / Surface skimmers / Float switches

Overview of lifting stations / Surface skimmers / Float switches

Lifting station

The contaminated medium coming out of the machine is gravity-fed into the adjacent lifting station. Special dirt pumps are used to transfer the dirt to the filter system. Special design features ensure that deposits as well as overfilling of the lifting station are avoided.

Advantages of lifting stations

- Small space required next to the machine

- Robust design due to use in dirty areas

- Low maintenance

- Tangential inflow

- Prevention of deposits

Areas of application of lifting stations

In central systems, the lifting stations ensure that the medium is fed to the central filter system. If feeding cannot be done by gravity in the case of single filters, lifting stations are necessary.

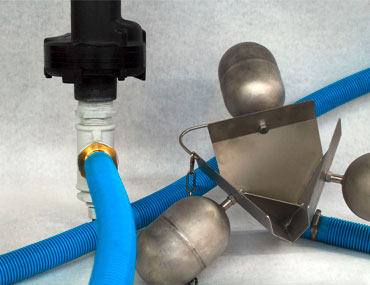

Surface skimmer

POLO surface skimmer collects floating particles such as foam, foreign oils, graphite and ultra-fine impurities in emulsion or wash containers and feeds them to a discharging system, e.g. a filter.

Advantages of surface skimmers

- Collects floating particles

- Easy to retrofit in existing systems

- Low maintenance

- Aeration of the medium

Areas of application of surface skimmers

For all liquid containers that have floating impurities on the surface.

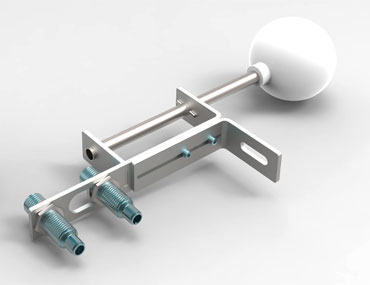

Float switches

By means of a floating body, microswitches or initiators are activated depending on the filling level.

Advantages of float switches

- Easy setting

- No downstream electronics required

- Can be used for all liquid media and containers

- Variable contacts and cable lengths available

- Long-lasting, robust material

- Safe and simple technology

- Easy retrofit

- Low maintenance

Areas of application of float switches

For example, float switches are used to switch pumps on and off. They protect pumps against running dry and prevent overfilling of your tank.